Ducati MotoE - The day has finally come to get to know the MotoE that Ducati has designed for the MotoE World Cup. Design, technical solutions, performance and the words of the protagonists of the first electric motorcycle made in Borgo Panigale.

The initials "V21L" in Borgo Panigale identifies the first Ducati electric motorcycle, a prototype that will compete in the FIM MotoE World Cup starting from 2023, of which the Bolognese motorcycle manufacturer will be a partner as a sole supplier with 18 bikes on the track during each race weekend.

The project MotoE has strategic relevance for Ducati as it allows it to develop skills for its future and to experiment with technological solutions in the world of racing, up to transferring them to motorcycles destined for production.

To make the prototype MotoE, Ducati has composed a team that unites Ducati and Ducati Corse designers, creating a mix of racing and product skills for such a technologically challenging project.

Ducati R&D took care of all Project Management activities, together with the design and simulations on the electric powertrain, while the design of the MotoE was entirely taken care of by the Centro Stile Ducati which also created the livery of the bike. Ducati Corse, on the other hand, worked on the design of the electronics, on the control and management strategies of the electric vehicle, on the simulations of the dynamics and aerodynamics of the motorcycle and finally on the assembly, track test and data acquisition processes.

The technical characteristics of the Ducati MotoE

The work of the Ducati MotoE team led to the birth of an electric motorcycle with unique technical solutions. Starting with the battery pack, the most binding and characterizing element in terms of masses and dimensions, which on the Ducati MotoE is characterized by a shape specifically designed to follow the natural course of the middle area of the bike. The battery pack weighs 110 kg and offers a capacity of 18 kWh with a 20-kW charging socket integrated into the tail. Inside there are 1.152 cylindrical cells of the "21700" type.

The Ducati MotoE has a total weight of 225 kg (12 kg less than the minimum requirements set by Dorna and FIM) and can count on maximum power and torque figures of 110 kW (150 hp) and 140 Nm respectively, which allowed it to reach a speed of 275 km/h on a circuit like Mugello (Italy).

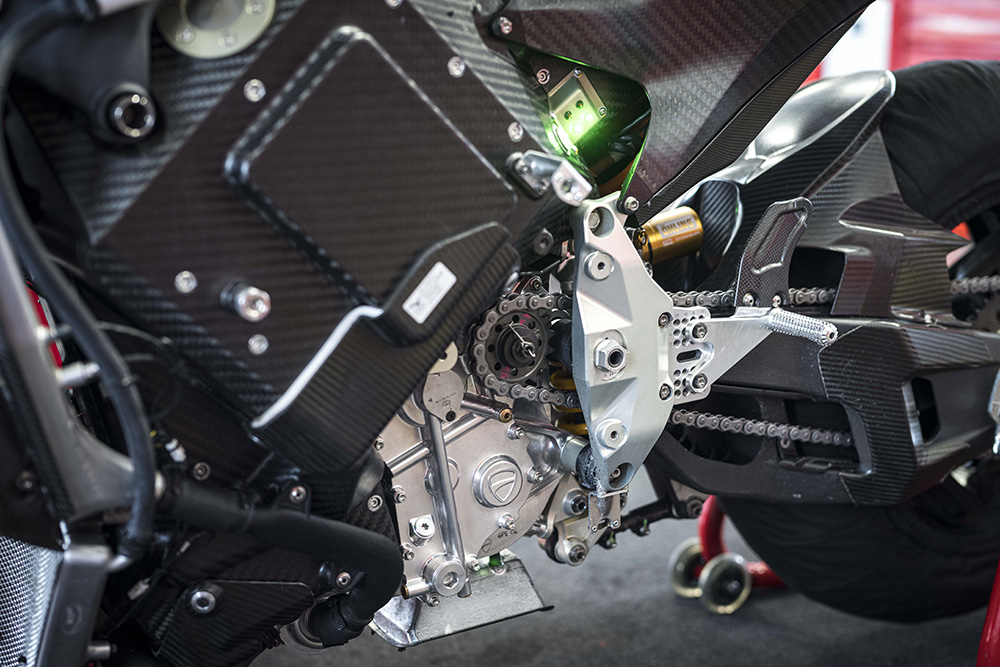

The inverter, with a low weight of 5 kg, is a unit derived from a high-performance model used in motor racing for electric vehicles, while the motor (21 kg weight and a maximum rotation speed of 18.000 rpm) was developed by a partner following the technical specifications provided by Ducati. The entire system is based on a voltage of 800V (with a fully charged battery pack) to maximize the output of the electric powertrain and, as a consequence, performance and range.

One of the most advanced technical solutions tested on the Ducati MotoE concerns the cooling system. The prototype components are in fact cooled by a particularly sophisticated and efficient liquid system with a double circuit designed to meet the different thermal needs of the battery pack and the motor/inverter unit. This guarantees extreme regularity of temperatures with important benefits in terms of consistency of performance but also in charging times. In fact, it is not necessary to wait for the battery pack to cool to start the process: the Ducati MotoE can be charged as soon as it enters the garage, and it takes about 80 minutes to recharge it up to 45% of its range.

The carbon fibre case of the battery pack also acts as a stressed part of the chassis, like what happens for the Ducati Panigale V4 engine, with an aluminium monocoque Front Frame for the front area weighing 3,7 kg. The rear is composed of an aluminium swingarm weighing 4,8 kg with a geometry like that of the Ducati Desmosedici racing in MotoGP. The rear subframe, which integrates the tail and the rider seat, is made of carbon fibre.

The suspension area features an Öhlins NPX 25/30 pressurized fork with 43 mm diameter upside-down tubes at the front, derived from the Superleggera V4, while an Öhlins TTX36 shock absorber is present at the rear and is fully adjustable. The steering damper is an adjustable Öhlins unit.

The braking system is supplied by Brembo and is sized for the specific requirements of the Ducati MotoE. At the front it is composed of a double steel disc with a diameter of 338.5 mm of increased thickness, which has fins on the internal diameter with the aim of increasing the thermal exchange surface area and improve disc cooling in conditions of extreme use on the track. Two GP4RR M4 32/36 calipers with a PR19/18 radial master cylinder operate on this double disc. At the rear, the P34 caliper acts on a single disc unit 220 mm in diameter and 5 mm thick with a PS13 master cylinder. Teams can also choose to equip their bikes with an optional rear brake control positioned on the left handlebar, which the rider can use as an alternative to the pedal one.

The development process of the Ducati MotoE also involved the Ducati Corse test team led by Marco Palmerini, who worked on the track applying the same methodologies used in MotoGP, thanks also to the support of the riders Michele Pirro, Alex De Angelis and Chaz Davies. Through the work on the electronics, the aim was to obtain a throttle response like that of an endothermic unit and a response from the electronic controls (such as Ducati Traction Control, Ducati Slide Control, Ducati Wheelie Control and throttle/engine brake maps) indistinguishable from that of the racing bikes that Ducati riders are used to.

The work plan of the Ducati MotoE project has already reached an advanced stage of development and will proceed towards 2023, the year in which Ducati will assume the role of sole supplier of the FIM Enel MotoE World Cup with 18 bikes on the track. The next goal for the Borgo Panigale manufacturer will be to take advantage of participation in the most important world electric motorcycle competition to experiment with new technologies, train new skills and study how to create, as soon as technology allows, a Ducati electric vehicle that is sporty, light, exciting and able to satisfy all fans.

In the next days we will publish further insights and analyzes on the MotoE of Ducati.

The test on track

It was during testing at Mugello in May that a video was recorded of an unprecedented start test with Chaz Davies riding the Ducati MotoE and Michele Pirro on the Ducati MotoGP. As you can see in the video below, in the first acceleration phase the two bikes perform very similarly, with 0-100% times of around 2,6 seconds.

Visualizza questo post on Instagram

Photo and video: Ducati

Interview with Claudio Domenicali

The MotoE of Ducati? With a light heart

To be updated on MotoE World Cup, subscribe to Epaddock's Whatsapp broadcast and receive all our news on your mobile phone in real time: find out how here.